Power Tools

- Table Saw

- Router Table

- Jig Saw

- Impact Driver

- Track Saw

- Spindle Sander

Wood

- 4/4 Cherry

- 3/4" Birch Plywood

- 3/8" Birch Plywood

- 1/2" Birch Plywood

- 1/2" Pine Plywood

- Ikea Gerton Beech Butcher Block Table Top

- Iron On Birch Edge Banding

Bits & Blades

- Flush Trim Router Bit

- 3/4" Core Box Bit

- 3/4" Round Over Bit

- 1/4" Round Over Bit

- 1/8" Round Over Bit

- 3/4" Drill Bit

Hand Tools

- Flush Trim Saw

- 1/4" Chisel

Hardware

- 24" Over-Extension Drawer Slides (Qty: 15)

- Incra T-Track

- Screws

When we purchased our home, the previous owners left their old workbench in the garage for us to use. It was a simply built 2x4 bench with a plywood sheet top and two large drawers that were barely hanging on for dear life. While it wasn't the highest quality bench by any means, we did our best to make use of it. It quickly became apparent that storage would be a problem. While the large drawers could hold a bunch of stuff, they were simply too large to sustain any sort of meaningful organization strategy. As I got more into woodworking, the storage issues only got worse and worse. For years, my miter saw simply migrated from spot to spot in the garage, usually somewhere right in the middle of the floor under a bunch of junk. Moving it around and clearing out space for cross-cutting lumber was an annoying chore. I desperately needed a better bench.

The old workbench.

The old workbench.

The inital model for my miter bench. Packing as much storage as possible into the bench.

The inital model for my miter bench. Packing as much storage as possible into the bench.

Mockup of the recessed miter saw table, the bank of cubbies built into the fence and storage for the planer below the miter saw.

Mockup of the recessed miter saw table, the bank of cubbies built into the fence and storage for the planer below the miter saw.

The new bench mostly assembled.

The new bench mostly assembled.

Still needs drawer fronts and the fence / cubbies.

Still needs drawer fronts and the fence / cubbies.

The fence. Melamine top with Incra T-track for a stop-block.

The fence. Melamine top with Incra T-track for a stop-block.

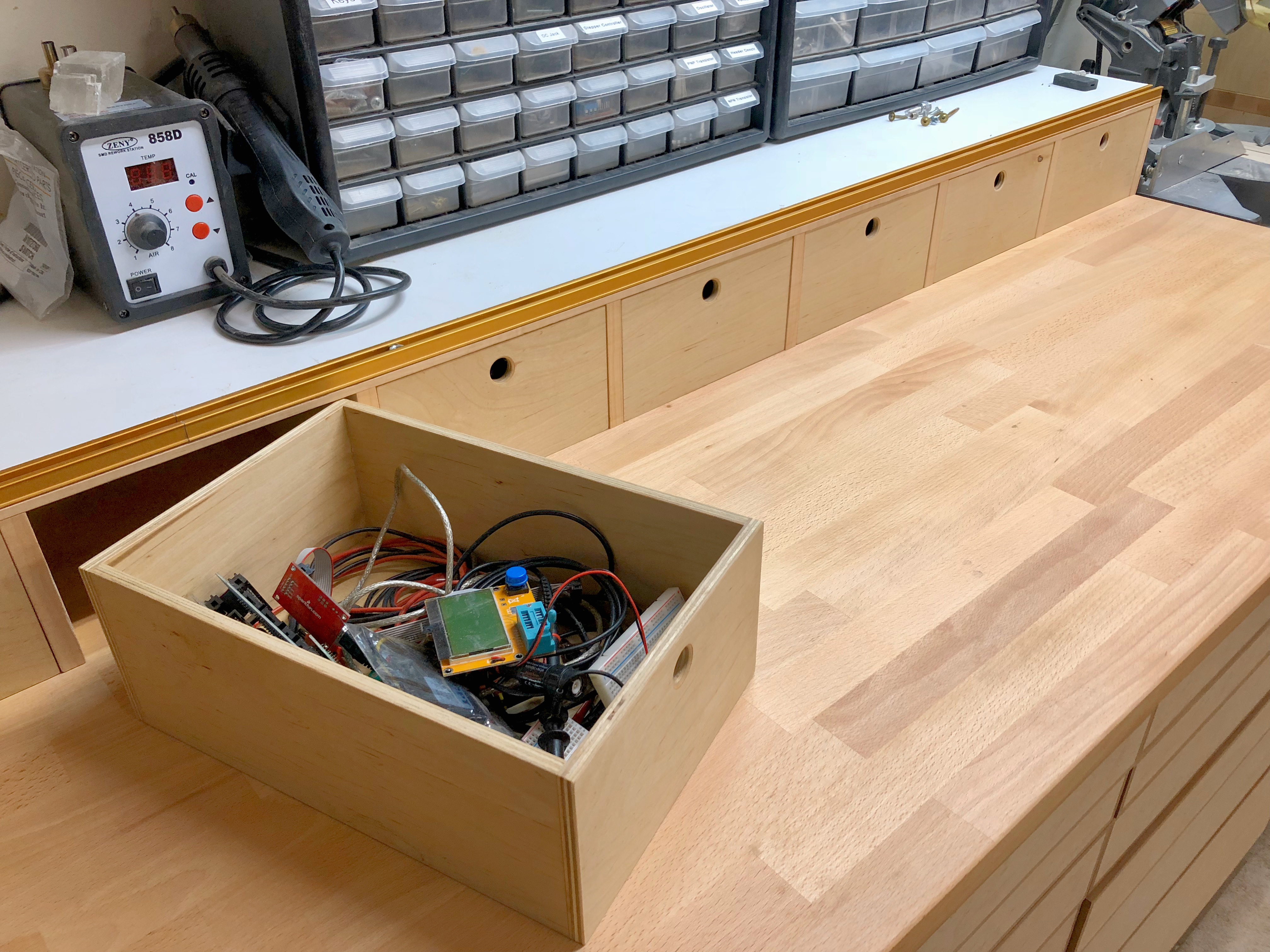

The cubbies are great for holding random odds & ends.

The cubbies are great for holding random odds & ends.

Lots of drawer parts

Lots of drawer parts

All the drawers mounted in the workbench

All the drawers mounted in the workbench

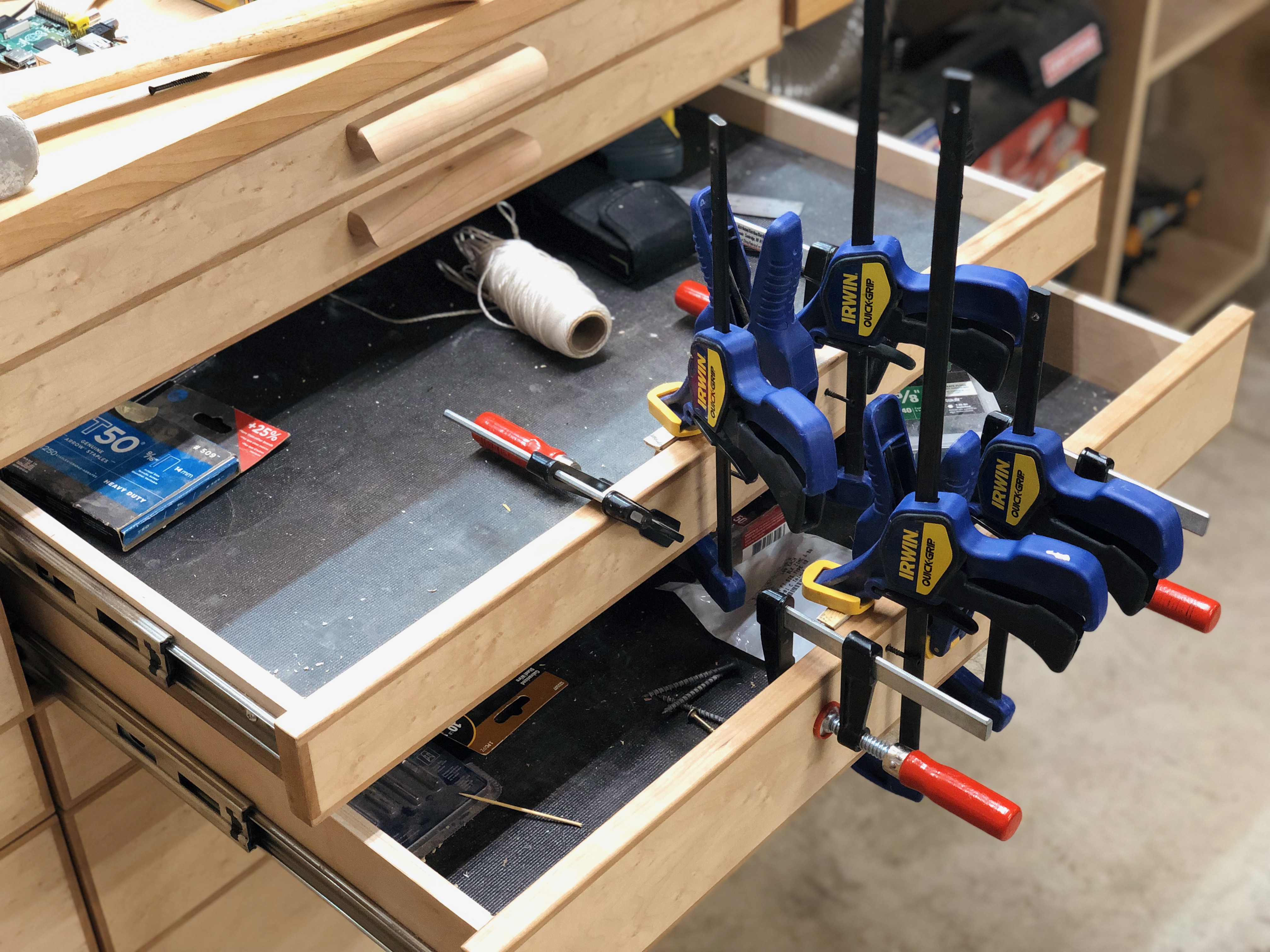

The drawers will never been this clean again

The drawers will never been this clean again

Milled up the edge banding for the drawer fronts to 1/4"x7/8" thick

Milled up the edge banding for the drawer fronts to 1/4"x7/8" thick

Drawer pull blanks ready for shaping

Drawer pull blanks ready for shaping

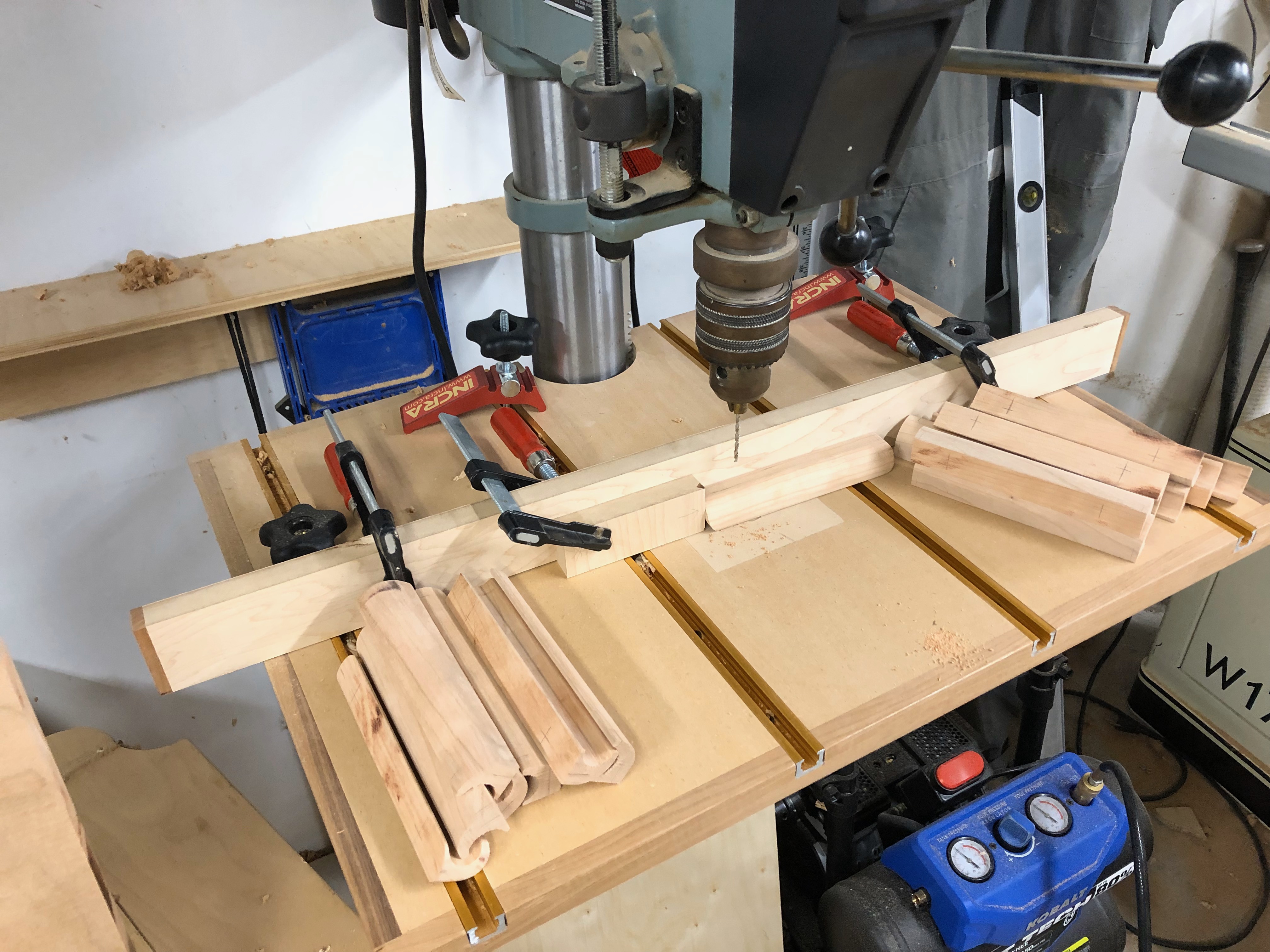

Using my new drill press table To predrill mounting holes for screws

Using my new drill press table To predrill mounting holes for screws

Had to attach some extra wood to securely mount the pulls.

Had to attach some extra wood to securely mount the pulls.

The finished pulls mounted to the drawers.

The finished pulls mounted to the drawers.

Download Plans

Download Plans